In certain industries, the adoption and emergence of tech when embraced can be truly game-changing. And none more so than the manufacturing industry. Specific technologies have been mooted as potential game-changers while others have been slower to emerge. But it could be the combination of these where the real revolution happens. Let’s kick off with three specific technologies that are having and will continue to have an impact in 2018.

3D printing

This has carried the game-changing moniker for a while without really taking off in the manufacturing industry. However, great strides have been taken in the aviation industry, specifically with the GE turboprop ATP engine.

35% of the engine has been 3D printed, which instantly drops the number of components required from 855 to 12. It also makes it lighter and more compact, as well as promising 15% lower fuel burn and 10% higher cruise power than competitors.

The cost of 3D printing is going down and this is where it can really make a difference enabling new products to be developed and prototypes made in much smaller environments than traditional manufacturing. Smaller operations can therefore go global much easier. This means 3D printing is likely to be much more widespread to create toys, electronic parts and medical devices amongst many others.

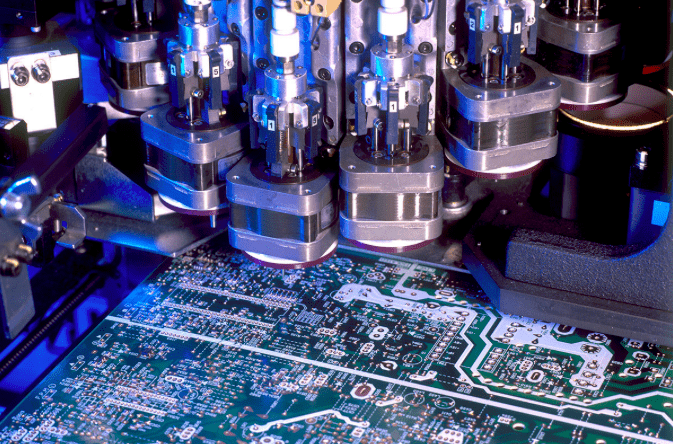

Robotics

This allows manufacturers to achieve new levels of precision, productivity and safety compared to humans. The use of robotics is expanding and adoption growing, with the manufacturing industry pioneering the way. By 2025, global spending on robotics in the manufacturing industry alone is expected to reach $24.4billion.

The biggest question mark when it comes to robotics is always going to be in terms of human labour vs. productivity. For the industry to evolve it is something that must be embraced, with the labour required having to change with the tech.

AI

The implementation of AI can be twofold. Firstly, AI algorithms can teach machines to make decisions on quality control, maintenance and a whole list of other factors, by perceiving data and discovering meaningful patterns based on experience. Secondly, algorithms can analyse and understand patterns of demand across geographical areas and markets, considering climate, political events and economic patterns. Both uses can be impactful for manufacturing.

Creating digital platforms and manufacturing ecosystems

But it’s the tech that’s able to unify these specific technologies that can be the true game-changer. And it’s this space that really interests us at Bolland & Co. Customers are changing, demand is evolving and with it the manufacturing industry needs to be agile. We’re now seeing more “customer pull” with customers involved in more of a collaborative relationship with manufacturers.

With the increased demand for personalisation, comes an increased requirement to truly understand the needs of the customer – clearly the correct application of data and analytics is key here. And this is where it gets interesting.

Those businesses that can solidify their position as digital platform and ecosystem providers are taking the industry to the next level. For example, think of a cloud-based system collecting customer data to facilitate transactions, logistics and operations from a variety of companies.

This means that those businesses with access to the platform will therefore have access to the customer data to develop better products and improve existing ones. It also means that the platform owner effectively owns the customer and becomes an aggregator type operative for the other enterprises.

It’s here with the likes of Product Lifestyle Management (PLM) systems and Manufacturing Execution Systems (MES) where the true game changing impact will be. And it all comes down to three things:

- An understanding of human behaviour and changing customer needs

- An understanding of the market as a whole

- An understanding of the capabilities of tech and how ecosystems can fulfil that changing customer demand

At Bolland & Co, in all our work we start with analysis of human behaviour and customer requirements, before creating the tech to respond to the individual challenges of the specific client and sector.

You can learn more about our client approach and results through our case studies, as well as our work in the manufacturing industry at one of our upcoming events.

www.abolland.co/events/